Description

Overview

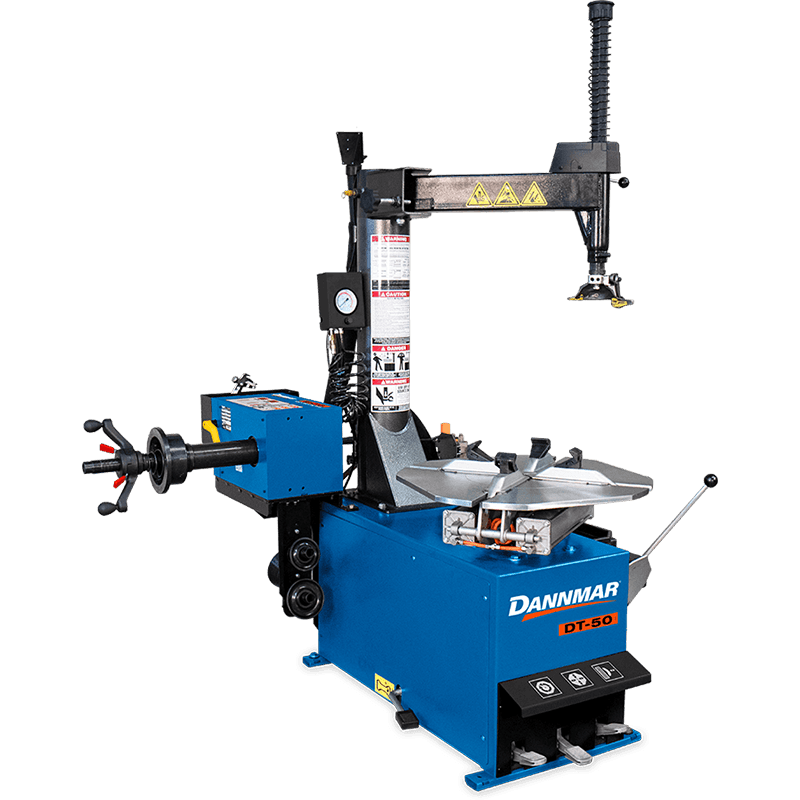

DT-50

Not only is the DT-50 affordable, but it also incorporates an intuitive design that will increase productivity. The controls are mounted upfront and are logically arranged to allow for both speed and ease of use. This tire changer is designed to handle the needs of an on-the-go shop with its durable body, rigid hexagonal vertical shaft, and its hardened-steel horizontal outrigger support arm which will eliminate flex during tire service operations. Not only that, but it will greatly reduce the risk of accidentally damaging wheels.

The turntable is ideal for fast operating speeds and features reverse-direction control which makes tire swaps even easier, especially for low-profile and run-flat beads.

This tire changer is crafted with an advanced bead breaker blade. Meanwhile a rubber bump-stop will ensure a smooth arm return, which will reduce shock loading.

Dannmar tire changers come standard with high-pressure polyurethane tubing that’s constructed with a smooth, seamless bore to improve flow.

Dannmar utilizes stainless steel and aluminum pneumatic cylinders. They’ve made sure that internal end-of-stroke cushions come within each cylinder. In doing so, they end up protecting the seal, wear band, and the piston rod.

The equi-dimensional shape of Dannmar’s mount and demount head will allow you to change tires without changing the position of the tool head. This tool head surface is manufactured micro-smooth.

A rigid 45mm spring assist hexagonal vertical tool shaft and hardened-steel horizontal outrigger support arm will make sure that the mount-demount tool head remains perfectly still during use. This will end up reducing the chance of accidentally damaging expensive wheels due to a loose or shifting tool head. The tire changer is fitted with linear guide bearings which make it easily adjustable to both vertical and horizontal wheel settings. These guide bearings require virtually no maintenance for the entirety of this tire changer’s lifespan. The non-flex horizontal arm boasts a hardened lower roller guide for controlled, balanced movements.

The DT-50 also includes a pistol-type inflator with a sure-grip clip-on valve chuck which has never been easier to operate. It also allows for full-function, hands-free operation.

MB-240X

The MB-240X is a manual-spin wheel balancer which is capable of working on wheels up to 26” diameter. This extremely accurate and dependable balancer makes use of proprietary Digital Sensor Technology for critical reliability and repeatability. This wheel balancer is perfect for use on high-end muscle cars with matching numbers, wheels, and tires. To top it all off, this top-of-the-line balancer delivers it all at an affordable price.

Features

DT-50

- Alloy steel mount and demount head w/protective plastic covers

- Traveling drop-center, top-mount helper/swing-in bottom helper disc

- High Torque Electric Turntable

- Adjustable Internal Rim Clamping – Capacity – 12” – 26” (305 mm – 660 mm)

- Maintenance-free gearbox

- Aluminum pneumatic cylinders

- High-pressure polyurethane pneumatic tubing

- Enhanced bead Breaker Blade

- Turbo-Blast Bead Seater

- Inflation Gauge with Integrated Air Dump Valve

- Tool Tray/Storage

- Soap Bucket

- Enhanced Bead Breaker Blade

- Oiler/Lubricator

- Optional motorcycle clamps

- Air Regulator

- Inflation restraint

- Forged steel foot pedals

MB-240X

- Basic dynamic wheel balancing function

- Balance an entire set of wheels

- Check the dynamic balance of suspected out-of-balance wheels

- Low-cost of ownership

- Computerized electronic data display for each balance

- Easy to use

- Good companion equipment to a Dannmar Tire Changer

- Quiet operation

- Perfect for small garages, car-hobby garages, or a backup

- Works well on many trailer wheels too

Specs

DT-50

| Motor | 110/220-VAC, 50-60 Hz, 1-Ph |

|---|---|

| Drive System Type | Electric / Air |

| Tower Design | Rigid Fixed / Swing Arm |

| Power Assist Tower | Not Equipped (See DT-50A) |

| Bead Seating System | Turbo Blast / Bead Seating |

| Air Requirement | 110-175 PSI (8-10 BAR) |

| Wheel Clamping Method | 4 Clamps – Internal / External |

| Table Clamping System | Dual Pneumatic Cylinders |

| Bead Breaking System | Pneumatic Blade |

| Tower Design | Fixed |

| Internal Rim Clamping Capacity | 14” – 26” (356 mm – 660 mm) |

| External Rim Clamping Capacity | 12” – 22” (305 mm – 559 mm) |

| Turntable Rim Width Capacity | 3” – 15” (76 mm – 381 mm) |

| Bead Breaker Rim Width Capacity | 3” – 14” (76 mm – 356 mm) |

| Maximum Tire Diameter | 47” (1,194 mm) |

| Noise | <70 dB |

MB-240X

| Motor | 110-230 VAC, 50-60 Hz, 1-Ph |

|---|---|

| Cycle Time | 7 seconds |

| Balancing Modes | Multiple ALU Modes |

| Drive System | Ball Bearing / Manual |

| Wheel Braking | Hand Brake / Manual |

| Cones Included | Standard Cone Set |

| Max. Tire Diameter | 31.5” (800 mm) |

| Max. Tire Weight | 150 lbs. (68 kg) |

| Wheel Diameter Capacity | 12” – 24” (305 mm – 610 mm) |

| Wheel Width Capacity | 4” – 15” (102 mm – 381 mm) |

| Balancing Increments | 0.25 or 0.01 ounce |

| Balancing Speed | 140 RPM |

| Accuracy | +- 1 Gram (.035 oz) |