OFF GRID SYSTEM DESIGN AND SIZING

At off grid solar kits, we have the qualifications, accreditation and project experience, to deliver an Off-Grid solar system that exceeds expectations. We use proprietary, state of the art, solar performance analysis software, to design stand alone power systems, specific to location and power usage. You will not find a more capable team of off grid solar design engineers. If you desire a system that performs as it is suppose to, and delivers all year round, contact us now.

3 KW SYSTEM DESIGN SPECIFICATIONS

Our 3 kw system is a strong performer for a small house. Coming standard with a 3kw continuous rated off grid inverter with a large surge capacity, this unit will run general appliances listed in the table to the left comfortably. Contact us for a site specific design for your location.

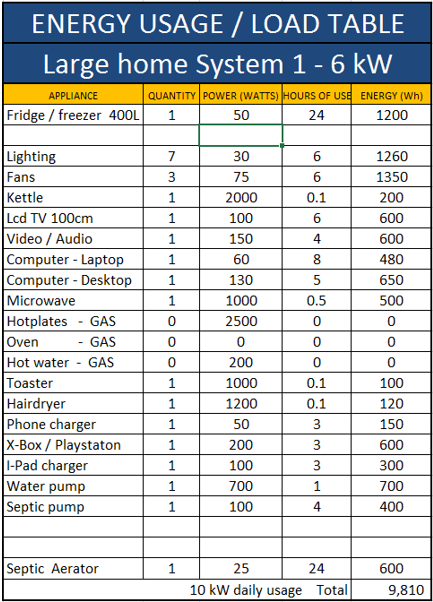

6 KW SYSTEM DESIGN SPECIFICATIONS

Our 6 kw system is a strong performer for a small house. Coming standard with a 6kw continuous rated off grid inverter with a large surge capacity, this unit will run general appliances listed in the table to the left comfortably. Contact us for a site specific design for your location.

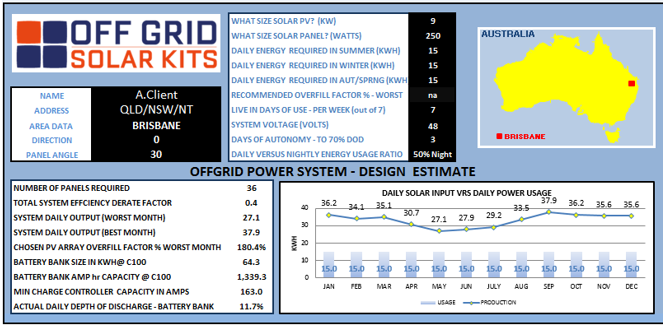

9 KW SYSTEM DESIGN SPECIFICATIONS

Our 9 kw system is a strong performer for a small house. Coming standard with a 3kw continuous rated off grid inverter with a large surge capacity, this unit will run general appliances listed in the table to the left comfortably. Contact us for a site specific design for your location.

Correct sizing by an experienced designer is crucial to a reliable off-grid power supply.

Our design team takes into account many factors including:

-

Site specific irradiance levels

-

Max and minimum temperatures

-

Panels orientation & tilt

-

Shading

-

Continuous load demands

-

Surge demand

-

Time of use

-

System inefficiencies

-

De-ratings

-

Max charge/discharge rates

-

Power factor

-

Usage autonomy

We size our systems around your power consumption, ensuring the battery bank has capacity for bad weather periods and the solar array can cover your usage, even during your area’s average worst month conditions.

To do this the first step is to assess your power requirements. To obtain a preliminary sizing our first questions will relate to the large consumers i.e. Hot water, cooking elements/ovens, air conditions, large pumps and workshop tools such as welders etc.

From this information and experience we can calculate general systems sizes and price.

Other indicators of usage may come from what you’re using in your current grid connected property, with your usage detailed in the bill. If/when more information is available we can carry out a load assessment that calculate power consumption from your appliances power usage and estimated run times.

With an existing system, running off a generator, we can supply energy usage meters to accurately record your actual power consumption.

Below are some examples of systems may be suitable for you.

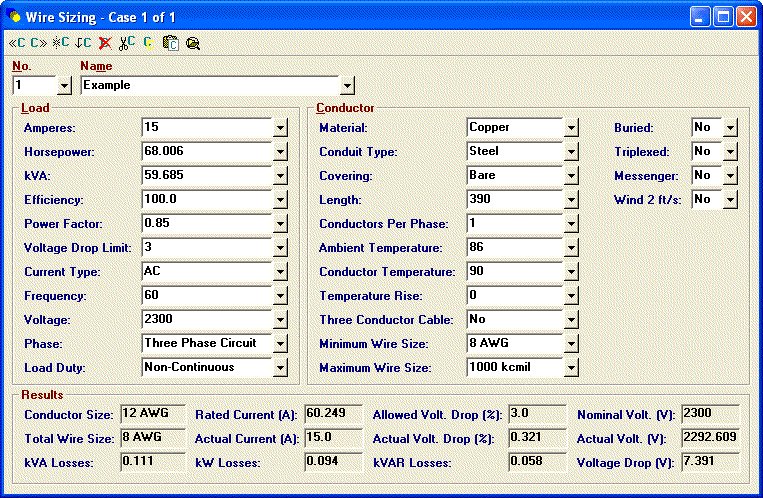

Installation calculations ensure a system perform’s appropriately.